ND NS SAMPLING

NEXIA ND/NS with the new, compact and captivating design.The machine NEXIA ND is provided with high speed dyeing system, this type of dyeing permits to reduce the use of the liquor ratio, the system also avoid any abrasion or knotting could happen during the operation. Another basic characteristic of this system is the complete penetration of chemicals even with the most delicate garment fiber, reducing considerably the time of the cycle operation.

|

|

|

CENTRIFUGING WASHING MACHINE FRONTAL TYPE FOR WASHING AND DYEING TREATMENTS OF SMALL PRODUCTION

The main revolutionary system of this new generation machine is the beaters, they are extractable and interchangeable with different shapes for various types of treatments. NEXIA ND sampling series has been projected to produce the same result and effect of the large production machine and satisfy any type of treatment. NEXIA ND/NS is available with OZONE treatment application, with both water and dry operations. |

|

|

|

ENERGY SAVING The space between the drum and the containment tank is reduced to the minimum, this characteristic permits to work with the minimum quantity of liquor ratio(1 to 4), consequently will save time, cost and to be ecological.

STRUCTURE The structure is completely made of stainless steel. |

PC CONTROL

AUTONOMY Indirect heating and cooling system through a coil placed in the tank of containment of dyeing bath. |

PROGRAMMING

SAFETY

|

TECHNICAL DATA

| TECHNICAL DATA: | 5 | 17 | 40 |

|---|---|---|---|

|

Drum Diameter mm.

|

700 | 950 | 1300 |

|

Drum depth mm.

|

390

|

700

|

900

|

|

Drum volume lt.

|

150 | 550 | 1200 |

|

Door diameter mm.

|

490 | 710 | 800 |

|

Capacity Max Kg.

|

5 | 17 | 40 |

|

Spin speed Max rpm

|

0-480 | 0-450 | 0-350 |

|

Power installed Kw

|

3 | 5,5 | 11 |

|

Voltage Volt/Hz

|

400/50 | 400/50 | 400/50 |

|

Products tank capacity Lt.

|

8 | 12 | 30 |

MACHINE SIZE

| MACHINE SIZE | 5 | 17 | 40 |

|---|---|---|---|

|

Width mm

|

900 | 1180 | 1560 |

|

Depth mm

|

1015

|

1465

|

1775

|

| Height mm | 1330 | 1700 | 2060 |

|

|

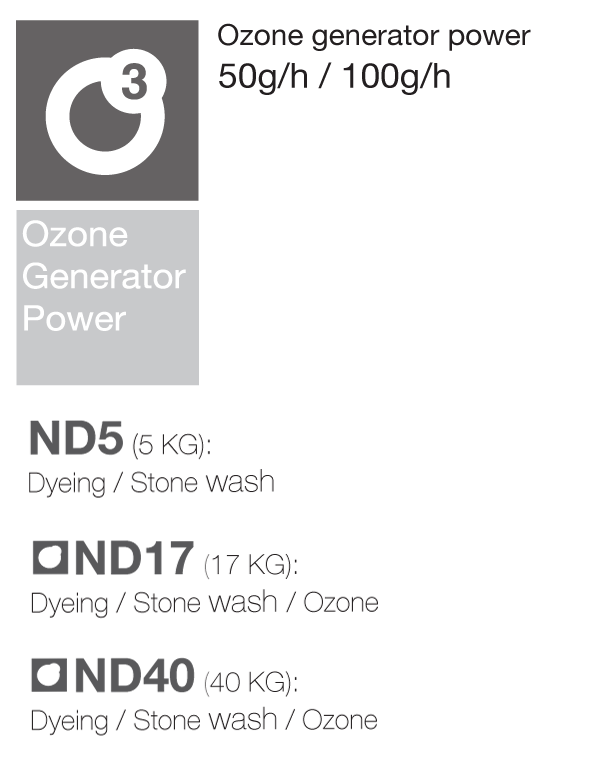

OZONE GENERATOR POWER

|